Laser Cutting Services

H V Wooding provides precision laser cutting in copper, aluminium and other metals using advanced fibre laser technology — enabling complex busbars, motor laminations and precision components to be produced without specialised tooling.

Our state-of-the-art Trumpf 3030 fibre laser cuts materials including copper (0.3–8mm), aluminium (up to 20mm), stainless steel (up to 20mm), mild steel (up to 25mm) and brass (up to 8mm) with exceptional speed, accuracy and edge quality. The system’s TruDisk solid-state laser and single cutting head with collision protection deliver high reliability and fast throughput, while its ability to process reflective metals such as copper and brass ensures consistent results across a wide range of applications.

Combined with advanced deburring, electroplating and in-house finishing, we deliver clean, accurate components and sub-assemblies for sectors including EV and hybrid vehicles, renewable energy, power electronics and research — all with efficient lead times and optimised part geometry.

Watch our Laser in action

Laser-Cut Busbars

H V Wooding manufactures precision-engineered copper and aluminium busbars for customers across the energy, electric vehicle, and industrial sectors. Our advanced laser cutting capability enables busbars to be produced rapidly and with exceptional accuracy, supporting prototype development, repeatable volume production, and seamless integration with our in-house coating and plating services.

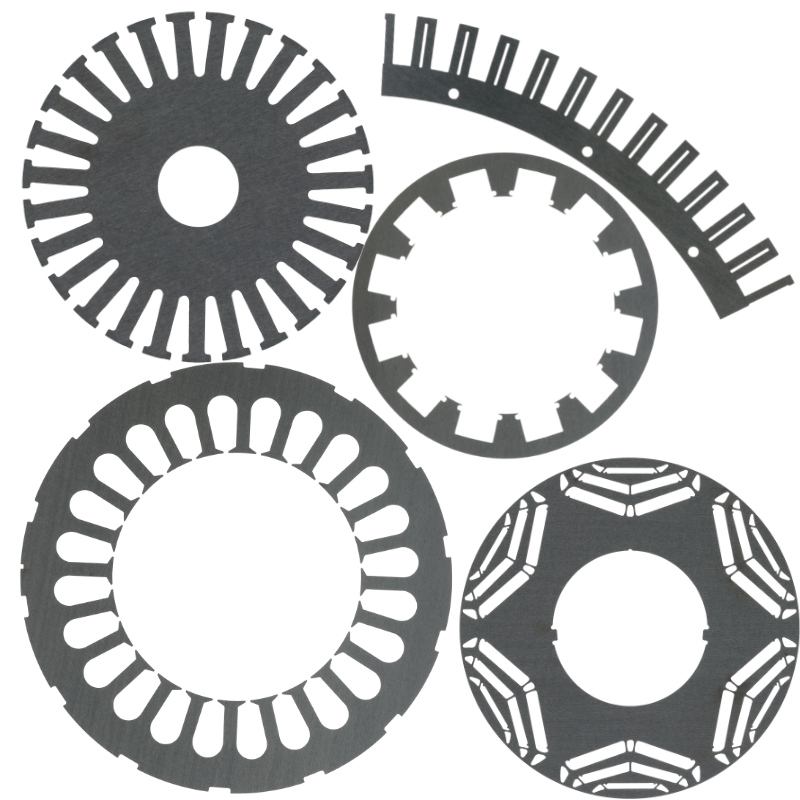

Laser-Cut Laminations

Laser cutting is ideally suited to prototype and early-stage lamination stack development before tooling is introduced. We manufacture both single laminations and pre-bonded stacks for testing and evaluation, with the ability to transition to stamped production once volumes increase. This ensures consistent geometry, precision and repeatability across all production stages.

Quality and Compliance

All laser cutting operations are backed by our ISO 9001, ISO 14001 and ISO 45001 certifications. Every stage of production is monitored through in-process and final inspections using advanced CMM and vision systems. We provide full traceability and can support customer quality processes with PPAP documentation, FAIRs and material certification where required.

Rapid Quotes and Prototypes – talk to our team today

As a trusted UK manufacturer with over 50 years of experience, H V Wooding delivers repeatable precision in every project. From prototype development to large-scale production, our laser cutting services UK are tailored to meet demanding specifications across energy, transport, and industrial sectors

We offer fast turnaround from enquiry to production, with same-day or next-day quotations available upon request. Customers can send DXF, DWG or STEP files directly to our engineering team for review. We also provide design-for-manufacture advice to help optimise parts for production efficiency, performance and cost reduction.

For more information or to request a quote, contact our laser cutting specialists on +44 (0)1303 264471 or email sales@hvwooding.co.uk. Our team will be happy to discuss your project requirements and provide expert advice on material selection, tolerances and production options.