Electroplating services

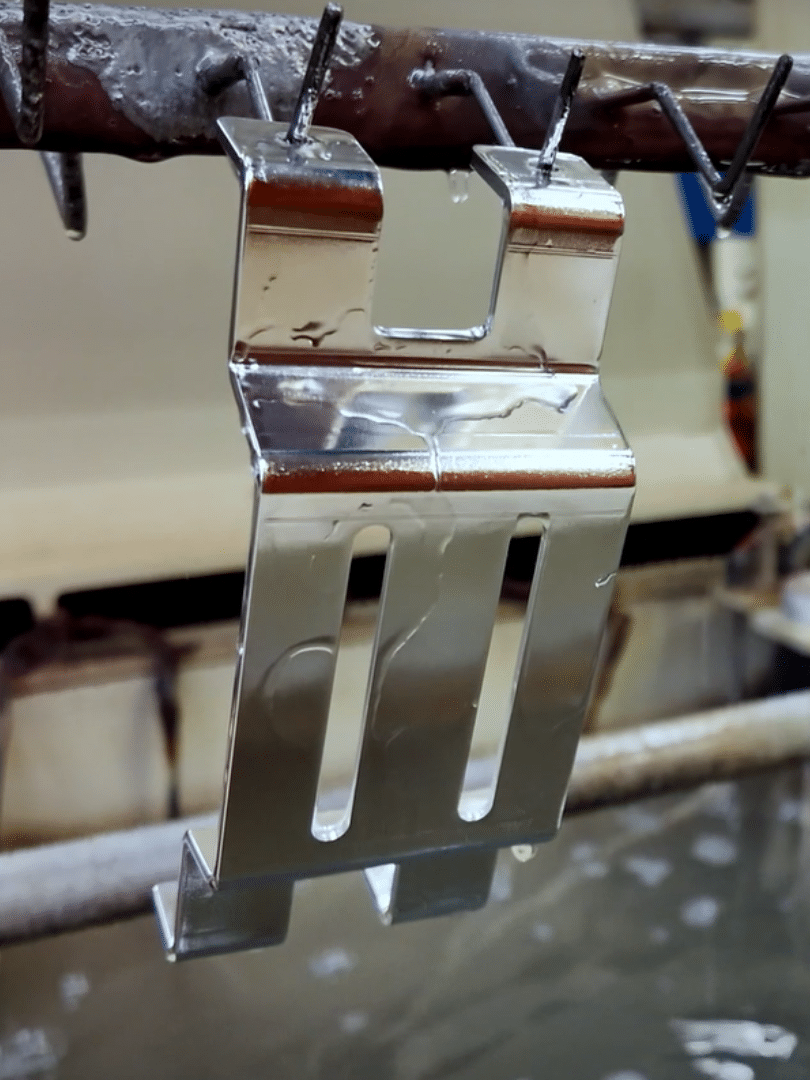

H V Wooding operates a fully equipped in-house electroplating facility, offering tin, zinc, nickel and silver finishes. By keeping this process on site, we maintain strict quality control and deliver consistent performance across every project. Both rack and barrel plating options are available to suit a wide variety of components and production volumes.

Electroplating provides not only aesthetic improvements but also critical functional advantages. Coatings stabilise electrical contacts, prevent corrosion and optimise tribology, enhancing the long-term performance of parts in demanding applications. Our experienced team works closely with customers to recommend the most suitable coating for each project.

Our Capabilities

To ensure precision, we maintain our own laboratory for monitoring and balancing chemical plating solutions, supported by advanced X-ray facilities that verify coating thickness and dimensional accuracy. Every batch is subject to stringent quality checks, guaranteeing compliance with customer specifications and industry standards.

With decades of expertise in precision manufacturing and finishing, H V Wooding provides electroplating services trusted by leading names across multiple industries, from prototype development to full production.