Motorsport & Niche Vehicles

H V Wooding are experts in the provision of manufacturing services to the high end Motorsport, F1 and Niche vehicle market including the manufacture of bespoke Busbars for battery and drivetrain applications.

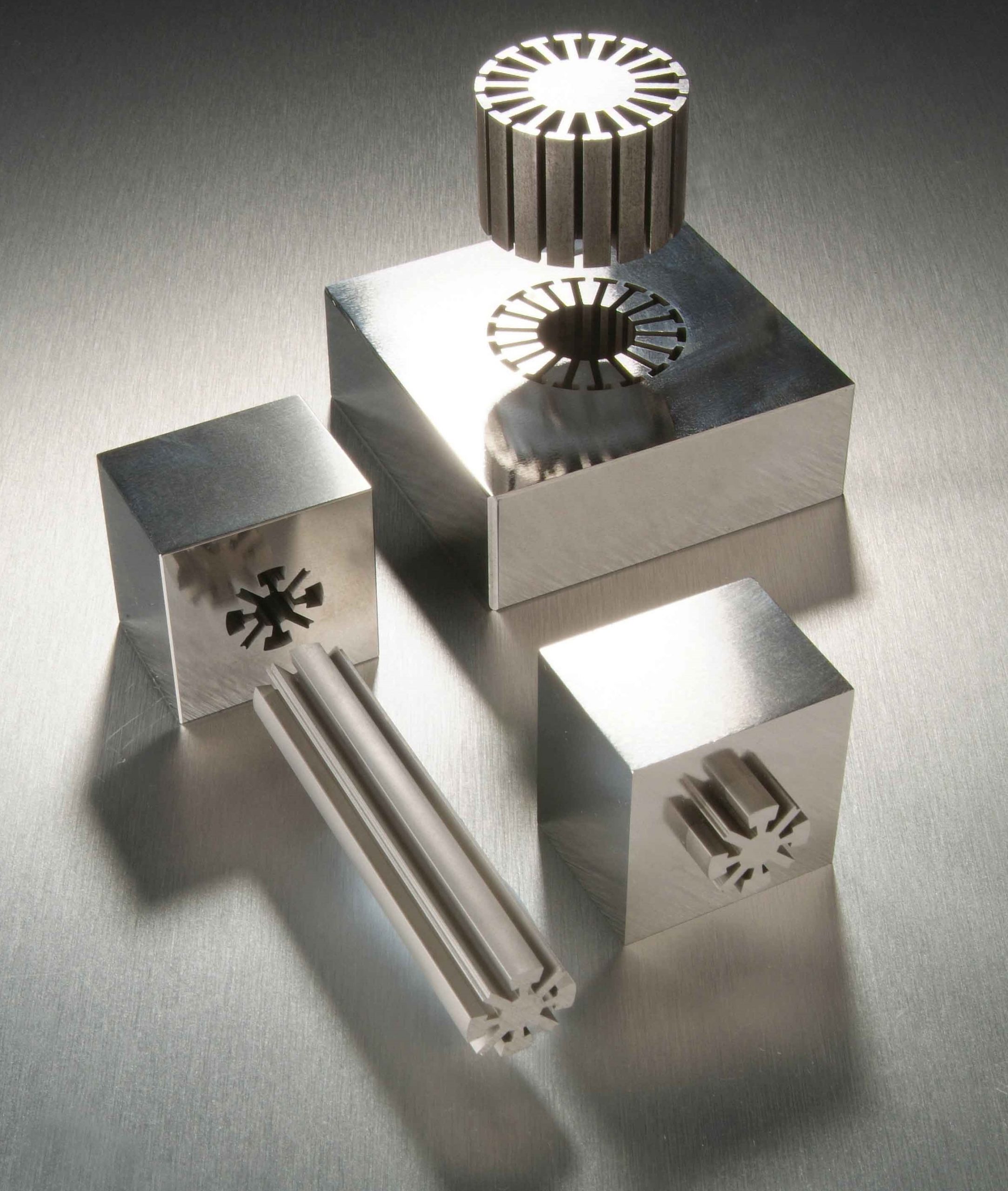

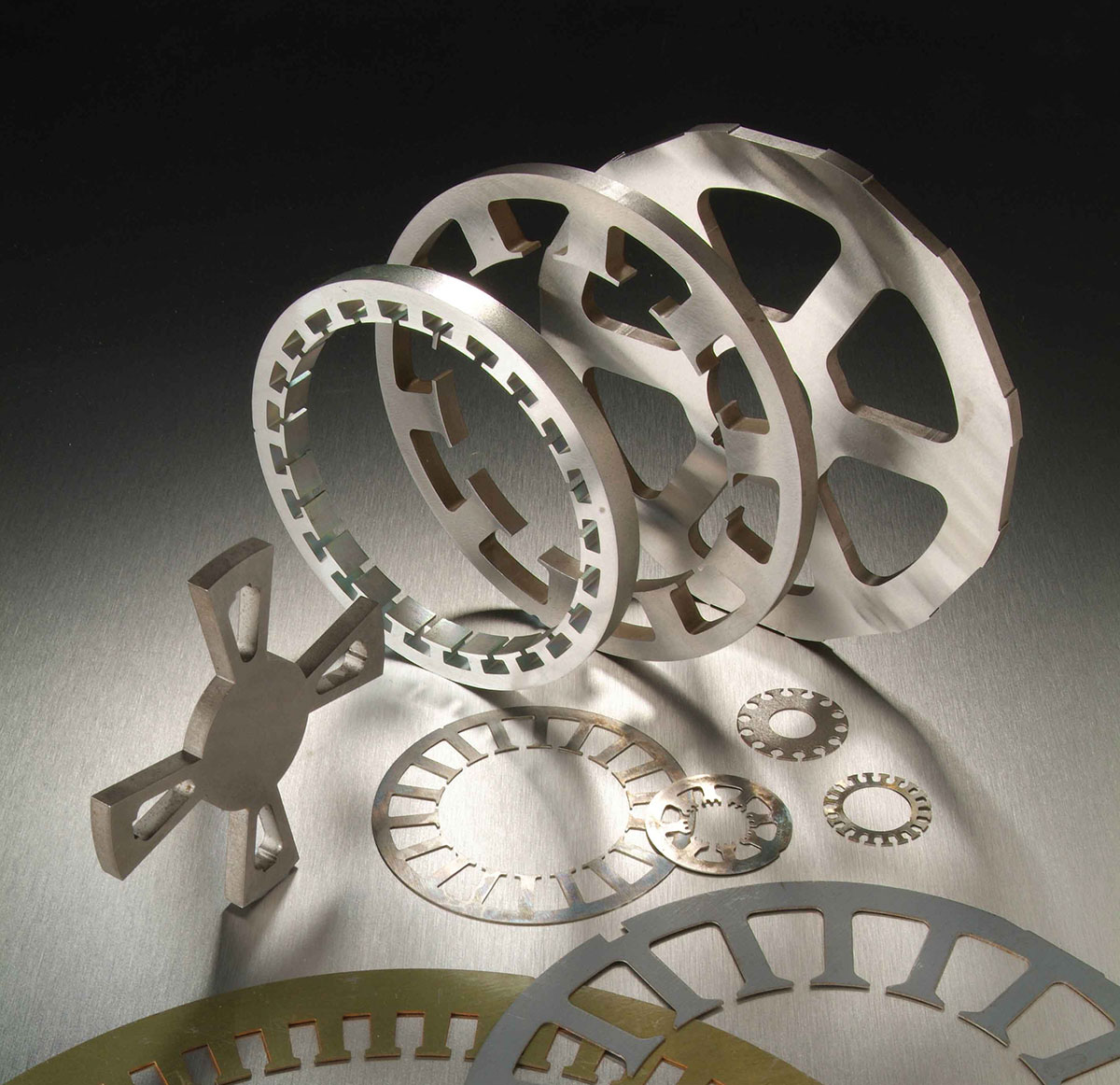

We are also leaders in the production of pre and post bonded Motor Laminations and Core pack assemblies, from prototype to volume.

Multiple manufacturing methods are available to suit your project utilising the latest Wire Erosion, Laser Cutting and Stamping technologies.

Our team of engineers can provide expert advice on the choice of materials and tolerances and a full support service, from initial samples through to volume production.

Clients include Mercedes AMG, McLaren and Williams Advanced Engineering– read our Case Studies for details of our added value services.

Find out more:

To explore how we could make a difference to your organisation, contact us for a free assessment of potential opportunities.